Electrical System Design

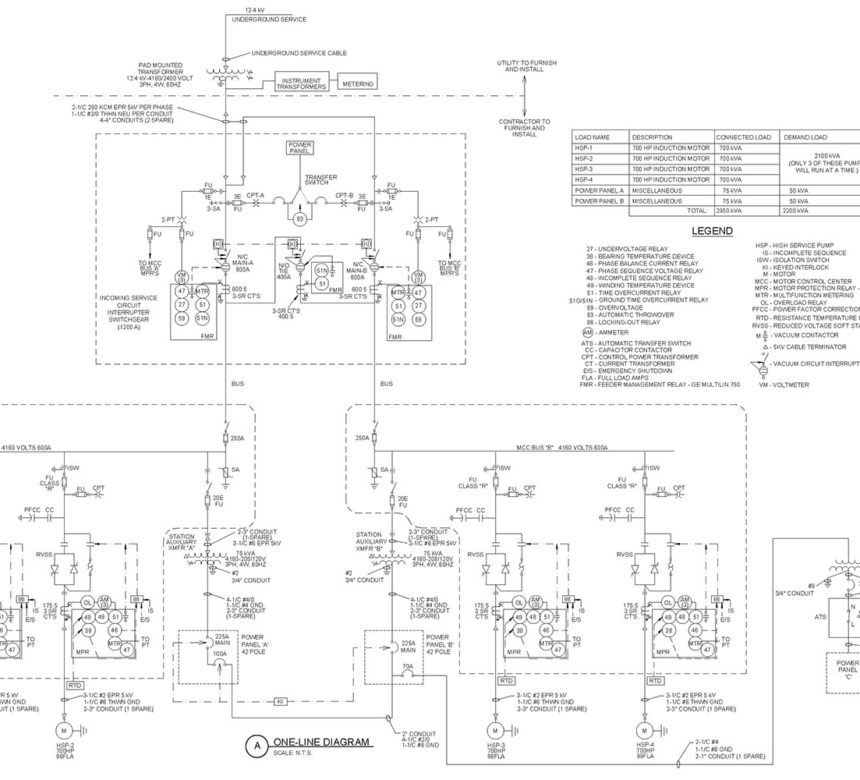

Design can be provided for power systems with voltages ranging from 120V (low voltage) to 4160V (medium voltage) and higher voltages. We have experience in commercial, industrial and utility design for existing and new facilities. Specific design expertise includes:

- Potable Water Production Facilities

- Potable Water Storage Tank Facilities

- Potable Water Well Sites

- Waste Water Treatment Facilities

- Waste Water Odor Control Facilities

- Recycled Water Facilities

- Electric Substations, Transmission Lines and Distribution Lines

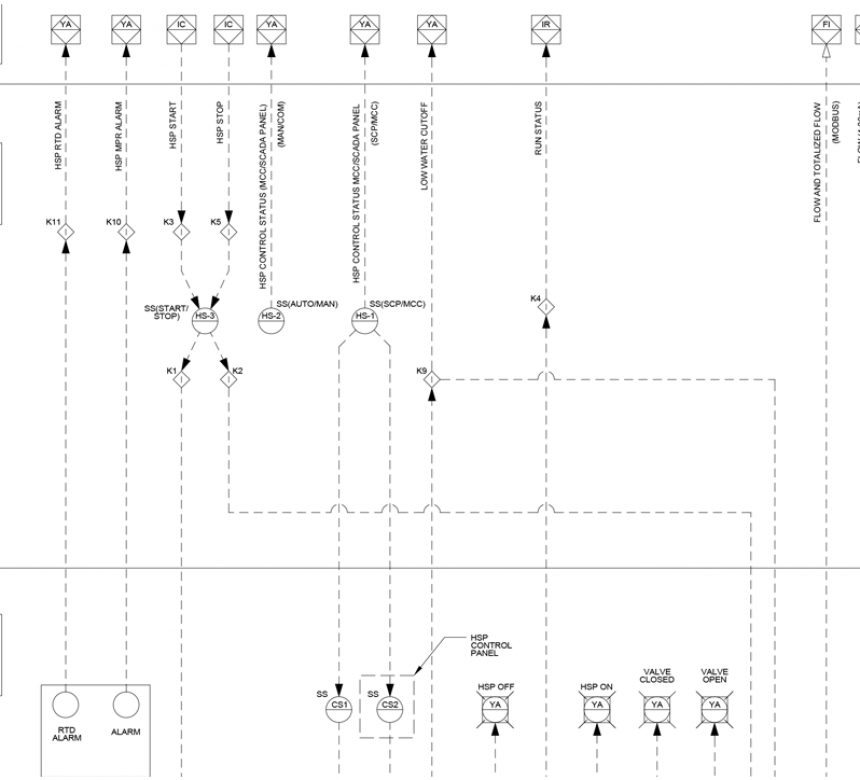

SCADA, Instrumentation and Control System Design

Design can be provided for Supervisory Control and Data Acquisition (SCADA), Instrumentation and Control Systems. These systems can provide control and monitoring for pumps, valves, treatment equipment and other process equipment. Instrumentation systems include flowmeters, pressure transmitters, level control equipment, chemical analyzers and much more. We have experience in design for existing and new facilities. Specific design expertise includes:

- Potable Water Production Facilities

- Potable Water Storage Tank Facilities

- Potable Water Well Sites

- Waste Water Treatment Facilities

- Waste Water Odor Control Facilities

- Recycled Water Facilities

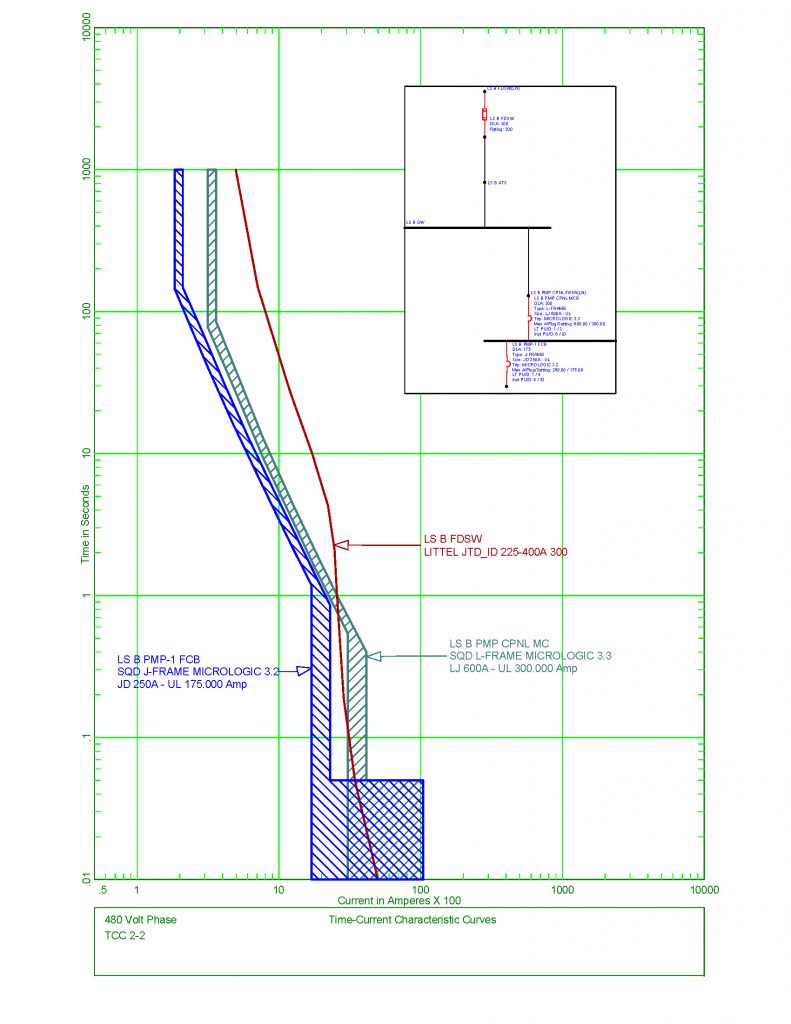

Power System Study

We provide computer generated studies that will determine protective relay settings to selectively coordinate the tripping of equipment, minimize damage for faults and protect personnel from the effects of arcing faults. A comprehensive report contains our professional recommendations for device settings along with a copy of all graphs involved.

Short Circuit Analysis

A short circuit analysis evaluates the potential maximum short circuit amperes that may arise during a fault condition. A short circuit is an accidental electrical contact between electrical conductors and/or electrical conductors and ground. The most common types of faults are three-phase, single line to ground, line to line, and line to line to ground. A short circuit analysis is important for evaluating withstand (bracing) ratings of electrical components that are being utilized throughout the system. It reveals if any inadequate components have been implemented or proposed that could create a potentially hazardous condition. Second, the short circuit analysis is vital for both the protective device coordination and the Arc Flash analyses.

NEC 110.9 requires equipment to have a rating sufficient for interrupting the maximum available fault current present at the line side terminals of the equipment. NFPA 70E Article 210 also requires electrical equipment to have appropriate ratings to withstand or interrupt the available fault current. Where the calculated available fault currents exceed the ratings of the equipment, action is required to possibly upgrade or replace the affected equipment for compliance with the NEC, NFPA 70E, and OSHA regulations. A risk of equipment damage, property damage, and personal injury exists when equipment has either inadequate withstands ratings or contains overcurrent protective devices (OCPDs) with inadequate interrupting ratings. Equipment with inadequate ratings in this category can suffer damage which may include bent busbars, melted contactors, ruptured enclosures or OCPDs may not be able to interrupt faults (three –phase bolted or arcing) properly.

Protective Device Coordination Analysis

A protective device coordination analysis determines the stability of the electrical system and is critical for performing an Arc Flash analysis. The objective of the protective device coordination analysis is to keep the power system uninterrupted by isolating only the components that undergo a fault, while maintaining as much as possible of the system in operation. This helps minimize unnecessary outages and avoids costly down time.

Selecting and setting the overcurrent devices is a procedure where the time-current characteristic curves of the various devices in series are compared with one another on a log-log graph. This procedure should take into account boundaries defined by load currents, short circuit currents, and ANSI and NEC requirements. Coordination usually will be obtained when log-log plots of time-current characteristics show sufficient clear space (discrimination time) or no overlap between the curves for the protective devices operating in series.

Protective device coordination is the process of determining the “best fit” timing of current interruption when an abnormal electrical condition occurs. In some instances, miscoordination between protective devices can arise. When this occurs, the miscoordination must be evaluated to determine the impact to the system. In some cases, the issue can be resolved by implementing different types and/or different sizes of protective devices.

Arc Flash Hazard Analysis

An Arc Flash Hazard Analysis is required to make appropriate selection of personnel protective equipment (PPE) for all persons who might be exposed to an electrical arc flash. Arc flash protection requirements are promulgated by the National Fire Protection Association (NFPA), Standard No. 70E – “Electrical Safety in the Workplace”, most recently published in 2018. The National Electrical Code, Article 110.16 requires that all electrical equipment that is likely to require examination, adjustment, servicing, or maintenance while energized be field or factory marked, in a clearly visible location, to warn qualified person of the potential electric arc flash hazards. Equipment labels can be provided to indicate these hazards.

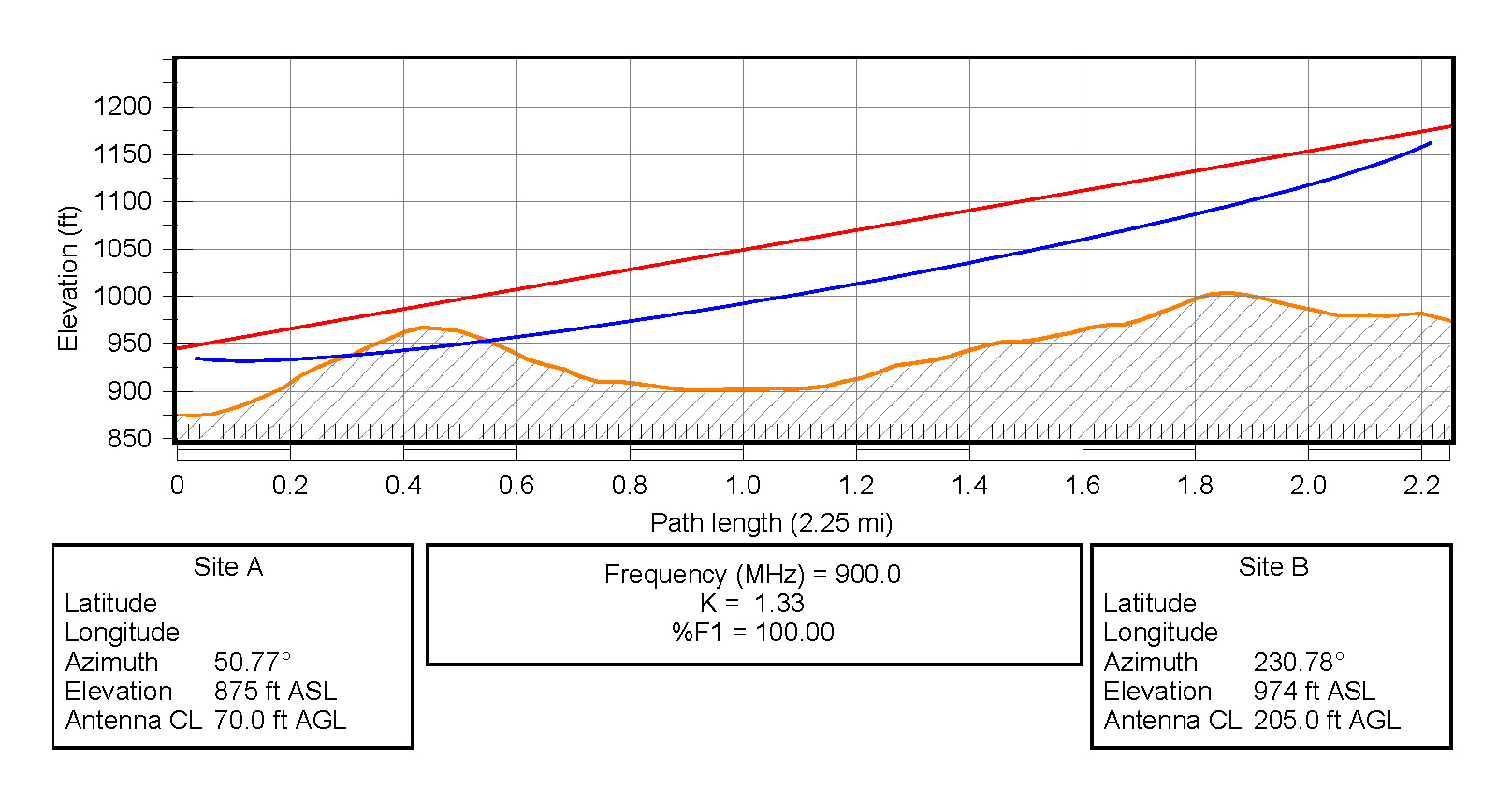

Radio Path Studies

Remote communication and control of systems via radio is vital to many utility systems including power generation, water and wastewater. We provide computer software based and physical radio path studies. The software study is completed first to determine which links would allow the most reliable communication. The physical study confirms or denies the software results by modeling the actual proposed installation. The actual proposed radio and antenna are lifted from the ground to a test height not exceeding 100 feet. If an existing radio repeater system is not installed we can provide a point to point test utilizing the same equipment on both ends.

Existing System

Evaluation and Analysis

Services include suggestions for optimum building operations for electrical, SCADA , instrumentation and controls equipment in existing environments. Grubb can suggest which equipment needs to be upgraded and prepare design documents, cost estimates and reports to allow the customer to evaluate options for upgrading.

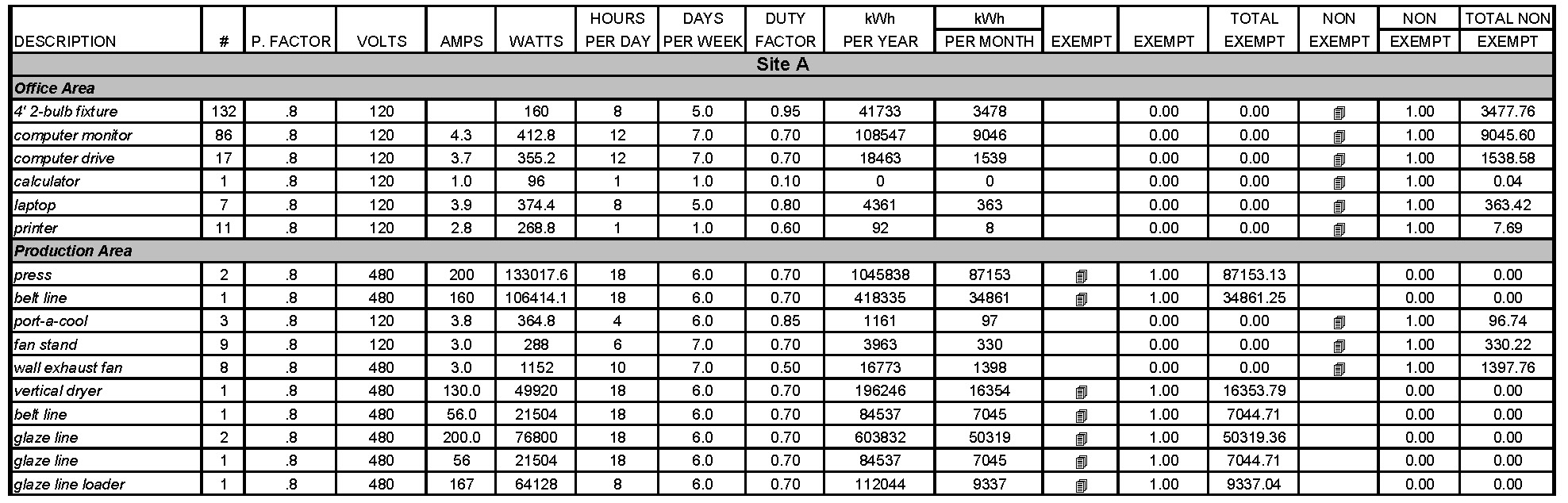

Predominant Kilowatt Usage Study

Electricity used for manufacturing purposes is considered non-taxable under the State of Texas, Sales and Use Tax Code 151.317. Where a single meter is used for manufacturing and commercial (taxable) purposes, a study must be performed and submitted to the utility for sales tax exemption. This study, which is certified by a Licensed Professional Engineer in the State of Texas, can be provided.

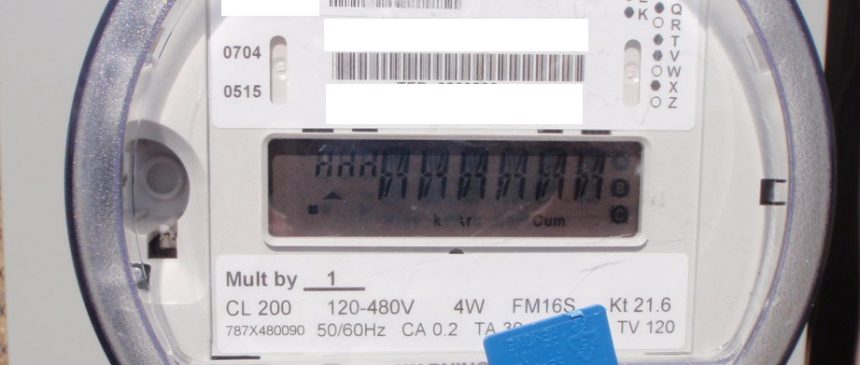

Energy Management

Depending upon your utility tariff you may be paying too much for your electricity. An evaluation of overall power consumption can be performed to determine ways to correct power factor, limit peak demands and shed load in an effort to reduce utility costs. The result will be reduced utility bills, which quickly pay back and continue to save you money.

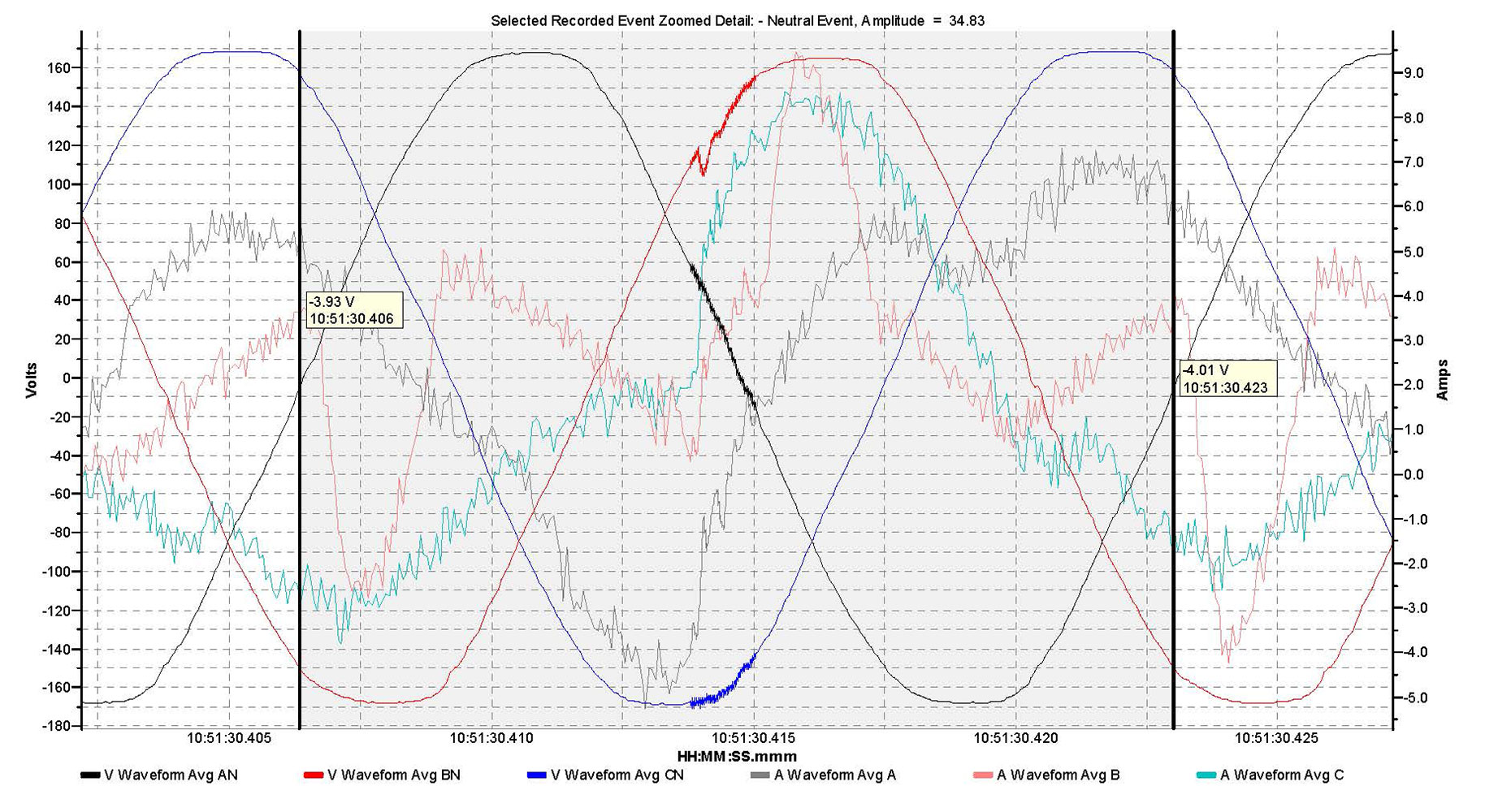

Power Quality Analysis

Do not let poor power quality keep your equipment from working efficiently, reducing your company’s profitability. Grubb Engineering utilizes reliable power meters and numerous recorders to monitor and capture the electrical parameters on a power system, including loads, voltage events, power consumption and overall power quality. Industry now recognizes power quality engineering as an important discipline. Grubb is no exception. That is why we have a group of engineers that review all of the data collected by our field service technicians and make observations and recommendations. The power measurement instrument, power treatment methods, and an information base are now available to permit companies, as yours, not only to determine the level of vulnerability to power disturbances but to influence their rate of occurrence as well. The electrical utility company, or electrical supplier, has long been viewed as the major source of power disturbances. This is not generally true. Electrical problems within the facility, large switching loads (i.e. VFD’s, UPS systems, rectifiers, computer servers), and the stress placed upon the electrical system by nonlinear loads, are responsible for most power disturbances. Finding solutions for power problems is not simply desirable, it is mandatory. The economic survival of the facility depends in the reliable operation of its equipment.

A comprehensive report is generated for you, the customer, and a cover letter detailing points of interest is attached to allow for easier interpretation of the data reported. Assistance, by Grubb personnel, is supplied in the interpretation of the data if necessary.